Condition-Based Monitoring System

What is Condition Monitoring

Condition monitoring is the process of regularly monitoring the condition of a piece of equipment or machinery to identify any potential problems or issues. This can be done using various tools and techniques, such as vibration analysis, oil analysis, and temperature monitoring.

The goal of condition monitoring is to identify potential problems before they become serious, which can help prevent equipment failures and downtime. It is an integral part of a proactive maintenance program, which aims to reduce the need for reactive maintenance (such as repairs or replacements) and improve the overall reliability and efficiency of the equipment.

Why Use it in Your Maintenance

By regularly monitoring the condition of equipment, organizations can identify potential problems before they become serious issues, which can help to prevent equipment failures and downtime.

By identifying and addressing potential problems with equipment before they become serious issues, organizations can save money by reducing the need for costly repairs and replacements.

By regularly monitoring the condition of equipment, organizations can identify and address potential safety hazards before they cause accidents and injuries

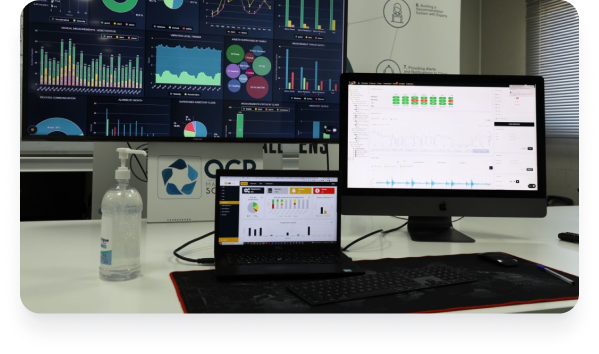

OCP Maintenance Solutions' Expertise

Our expertise lies in using advanced technologies and data analytics to provide real-time insights into the performance and health of critical assets. Our solutions help organizations improve equipment reliability, reduce downtime, and increase operational efficiency. Our team of experts has extensive experience in various industries and a deep understanding of the challenges faced by organizations in maintaining their assets. With OCP Maintenance Solutions, organizations can effectively monitor and manage their assets’ health, ensuring optimal performance and longevity.

How We Can Help You

At OCP Maintenance Solutions, we specialize in helping companies with their condition monitoring efforts. Our team of experienced professionals is equipped with the knowledge and skills needed to develop and implement effective condition monitoring programs that can help to improve the reliability, efficiency, and safety of your equipment.

Our services include:

- Vibration analysis: We use specialized sensors and software to monitor the vibration levels of your equipment, which can help identify potential problems before they become serious.

- Oil analysis: By analyzing the condition of your equipment’s lubricating oils, we can identify any potential problems with the equipment and recommend appropriate maintenance activities.

- Temperature monitoring: By monitoring the temperature of your equipment, we can identify potential problems before they become severe and recommend appropriate maintenance activities.

- Training: We offer training programs to help your team develop the skills and knowledge needed to implement and maintain condition monitoring programs effectively.

By partnering with us, you can benefit from our expertise and experience in condition monitoring, and we can help you optimize your equipment’s performance and reduce the risk of failures and downtime. Contact us today to learn more about how we can help with your condition monitoring efforts.

Frequently Asked Questions (FAQs)

Get in Touch with One of Our Experts

We will get back to you in under 48 hours

*by clicking the “Submit” button, you agree to provide us your personal details and confirm you have read and agreed to our Privacy Policy.